Part 1: General

1.01 Work Included:

A. Extent of sprayed on decorative/acoustical insulation is indicated on drawings.

1.02 Quality Assurance:

A. Provide Portland Cement-Vermiculite material, which has been tested to and achieved the following values:

| Property | Test Method | Value |

|---|

| Asbestos Content | EPA 400/4M-82-020 | No Asbestos

No Mineral Fiber |

|---|

| Density | ASTM E 605 | 41 lbs/cu ft |

|---|

| Compressive Strength | ASTM E 761 | 300 PSI |

|---|

| Bond Strength | ASTM E 736 | 5000 lbs./sq. ft. |

|---|

| Surface Burning Characteristics | ASTM E 84 | 0 Flame Spread

0 Smoke Developed |

|---|

| Sound Absorption | ASTM C 423 | 0.50 NRC @ 1/2“ Thick

0.60 NRC @ 1” Thick |

|---|

| Toxicity | University of Pittsburgh

Toxicity Test | LC 50 >300 Grams |

|---|

| Combustibility | ASTM E 136 | Non-Combustible |

|---|

| Hardness | ASTM D 2240 | 70 |

|---|

B. Provide testing results and procedures that have been certified by Cedar Knolls Acoustical Labs, or other accredited independent testing laboratories. Thickness of test samples must be determined and reported by acoustical laboratory. Nominal thicknesses are not acceptable unless peak thicknesses are also reported. Edges of acoustical test samples must be sealed with a wood or metal frame. Taping of edges is unacceptable..

1.NRC not less than 0.60 at 1 inch thickness and coefficient not less than 0.35, (+ or – 0.01), at 250 Hz. Conduct testing on solid backing with no air gap and sealed edges. Taping of edges is unacceptable.

C. Installer: licensed by manufacturer.

D. Control Sample: Prior to installation of final coat, apply an area of 50 sq. ft. in presence of architect, for approval of finish texture, as selected from samples.

1.03 Submittals

A. Submit manufacturer’s installation instructions, test data substantiating compliance with quality assurance.

B. Submit 12-inch square sample of sprayed on insulation showing texture variations for approval. Resubmit as required until approved. All samples must be certified by manufacturer that they are representative of the texture, which was acoustically tested in supporting acoustical test reports.

C. Submit test reports from all suppliers showing material to be 100% free of asbestos, mineral fibers, polystyrene and cellulose.

D. Submit certification of applicator licensing.

E. Submit acoustical test data for specified finish.

1.04 Material Handling

A. Keep material dry until ready for use.

1.05 Warranty

A. Manufacturer shall warrant the material to be supplied, agreeing to repair/replace that which has flaked, dusted excessively, peeled or fallen from substrate, or otherwise deteriorated to a condition where it would not perform effectively as intended for a sound absorbent purpose; due to defective materials and not due to abuse, improper maintenance, unforeseeable ambient exposures, or other causes beyond anticipated conditions by manufacturer. The warranty period will be 10 years from date of substantial completion.

Part 2: Products

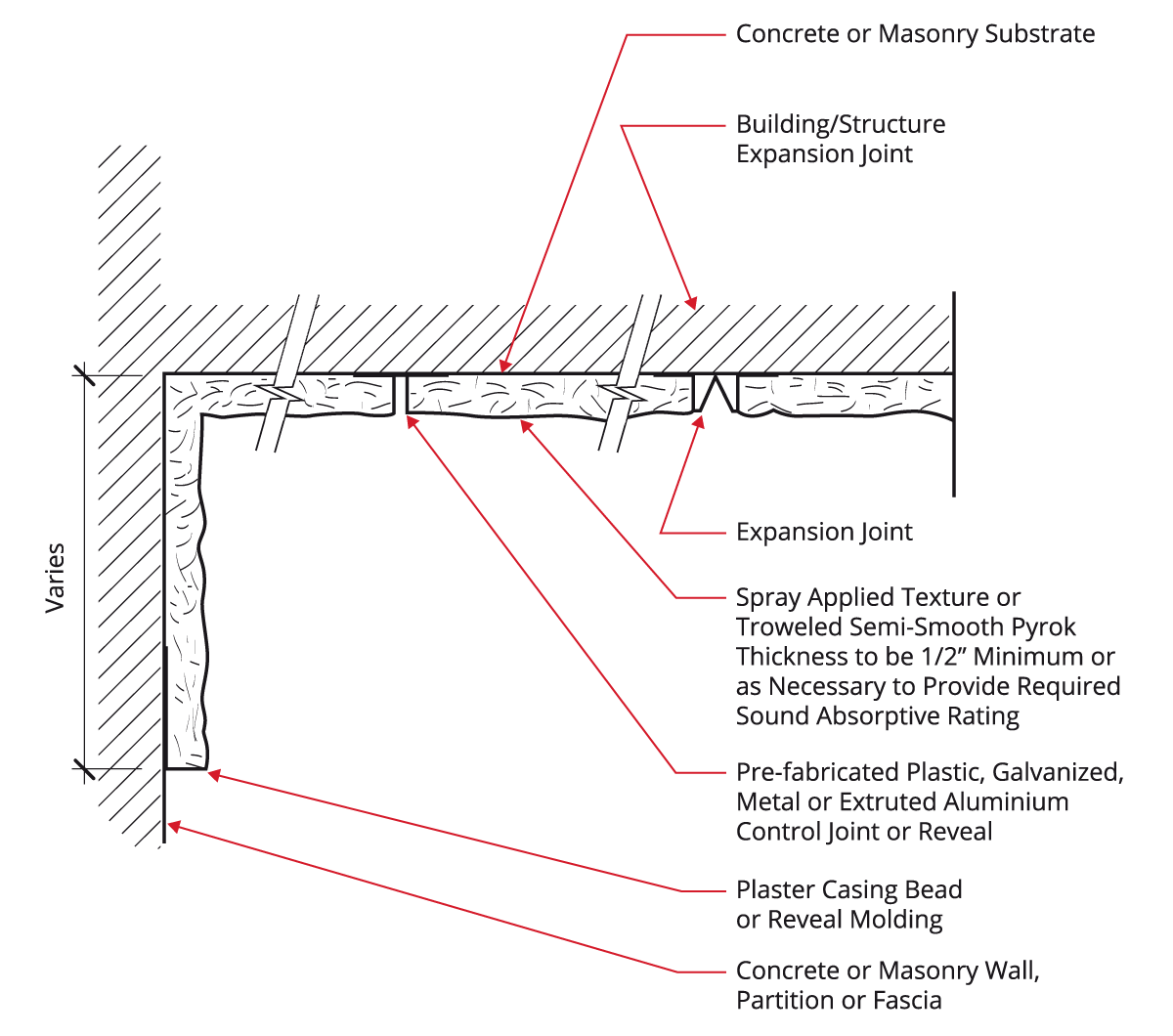

2.01 Materials

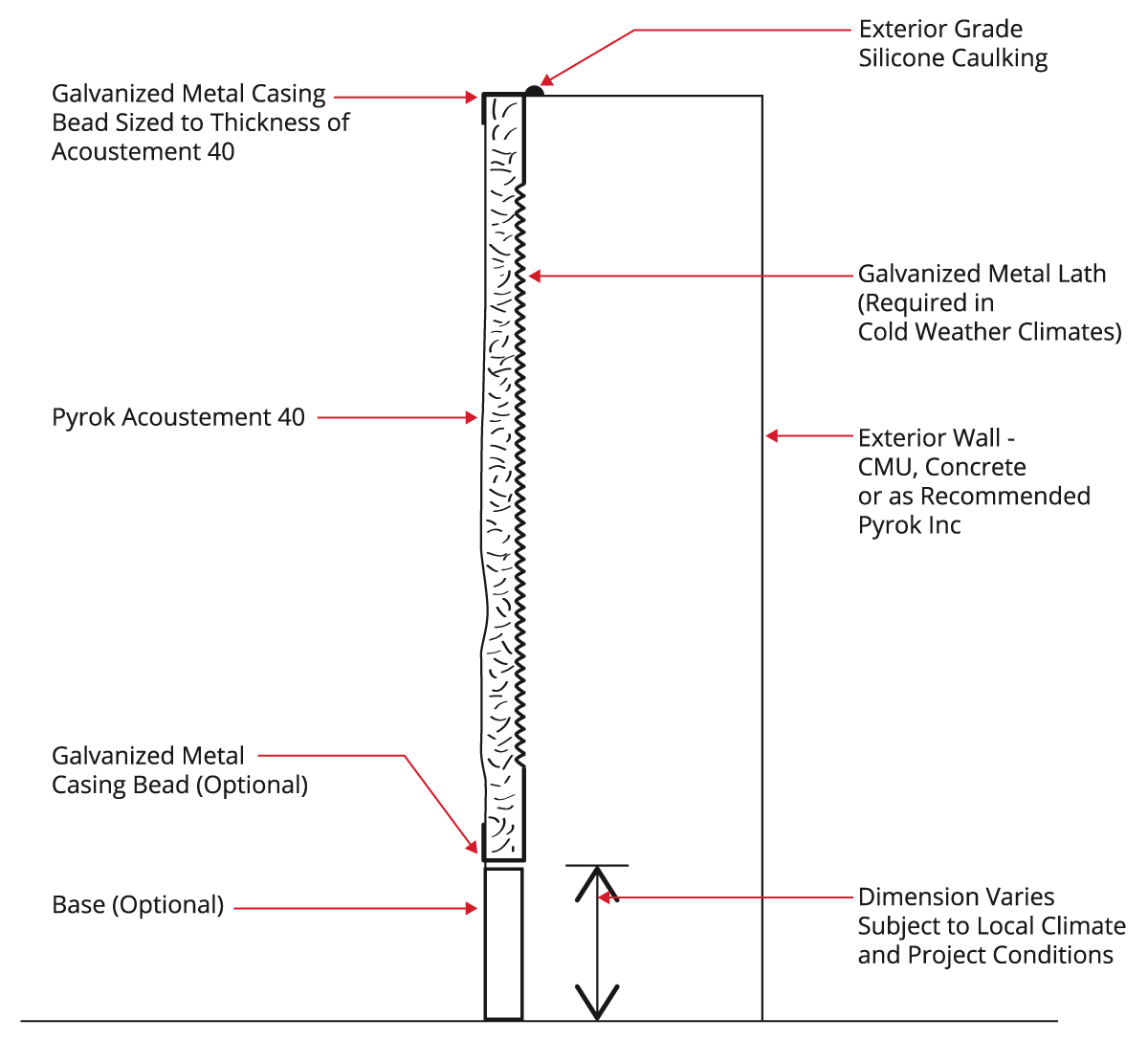

A. Materials shall be Acoustement 40 manufactured by Pyrok, Inc., Mamaroneck, N.Y. (914) 777-7070, or equal.

B. Color shall be __________ selected by the architect.

C. Texture shall be (standard texture) (semi-smooth trowelled finish).

D. Thickness shall be __________.

Part 3: Execution

3.01 Inspection and Preparation

A. Examine all substrate and conditions.

B. Assure substrate is free of oil, grease, dirt, paint, or other matter which would impair bond or install metal lath as recommended by the manufacturer.

C. Do not proceed until said substrate and conditions are acceptable.

D. Prepare substrate by filling voids and cracks and offsets, remove projections that result in telegraphing presence of imperfections.

E. Prime substrate with primer or bonding agent as recommended by the manufacturer.

F. Do not apply insulation material when temperature is below 44 degrees F (ambient), or substrate is below 40 degrees F.

G. Mask all adjoining surfaces in order to minimize damage from overspray.

H. Provide ventilation if required, and avoid excess drying rates.

I. Provide tarps or temporary enclosures as necessary to confine operations.

J. Perform all patching and repairing of insulation required to be done due to cutting, etc., by other trades.

3.02 Application

A. Apply in accordance with manufacturers printed instructions using any rotary stator plastering pump or other spray equipment approved by the manufacturer.

B. Install to thickness indicated or thickness required to achieve NRC specified.

C. Ensure that texture and color are all as per control sample.

3.03 Cleaning And Patching

A. Remove overspray and fall out material immediately upon completion of the work in each area. Clean surfaces to remove evidence of soiling. Repair or replace damaged work surfaces to acceptable conditions.

B. Coordinate work with other work, to minimize possibility of damage to insulation resulting from performance of subsequent work. As other units of work are completed in each area, patch damaged areas or surfaces of insulation by over spraying to match original installations, or by patching procedures as required to provide acceptable results.